Neoloy Geocell mineral and mining companies are adopting sustainability as a core value alongside the need to improve productivity. This article will discuss PRS Neoloy Geocells, an innovative soil stabilization technology that improves mining sustainability and productivity at the same time.

Mine sites often face extreme access challenges: they are typically located in remote locations, subject to extreme weather (rain or drought, cold or hot), suffer from soft soils (sand, peat, organic silts), and may even lack sources of construction aggregate. All of these impact haul road quality/condition, which directly affects haul truck productivity and operating costs. In a study of four Brazilian mines for example, monthly productivity decreases by an average of 47% during the rainiest months due to haul road degradation and the impact on truck rolling resistance (Mendonça, 2017).

Neoloy Geocells can help meet these challenges. Designed to stiffen road pavements – even with marginal infill material – Neoloy Geocells support heavy-duty equipment use on soft subgrade for the duration of the mine operating life.

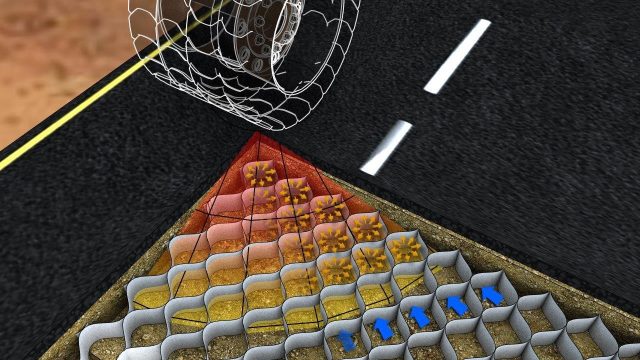

Neoloy Geocells are a 3D honeycomb geosynthetic made from a nano-technology alloy, Neoloy®. When filled with soil and confined, the stiff cells prevent lateral soil movement resulting from vertical loading. The result is a durable stiffened layer that can sustain long-term heavy loading. Unlike short-term geocells usually made of HDPE or fabrics, geocells made of Novel Polymer Alloys (NPA) are designed for durable engineering applications relevant to the mining industry. The creep resistant and high elastic stiffness properties of the Neoloy polymer guarantee reliable, heavy-duty soil stabilization.

Neoloy Geocells can also be used to solve mine site problems of soil erosion, slope instability, and waste containment with sustainable solutions for site rehabilitation and geomembrane protection. The following sections will show how mining sites benefit from the use of Neoloy Geocells to improve sustainability, safety and operational productivity:

1. Sustainable Haul Roads

Haul roads are the lifeline of mining but face constant challenges. Heavy seasonal rains, for example, impact hauling operations, degrading roads and lowering haul truck productivity. This is where Neoloy Geocells are effective. Neoloy Geocells stabilize soft soils, increase aggregate strength, and improve load distribution to make unpaved haul roads stiffer, stronger and more durable. Neoloy Geocell haul roads are fast to build, enable all-weather operations and extend the road life-span beyond the operating life of the mine.

The high Neoloy Geocell reinforcement factor is due to its high dynamic stiffness, resistance to permanent degradation and tensile strength. Neoloy Geocells improve the structural and functional behavior of infill materials, enabling:

- Construction of durable haul roads on soft subgrade (sand, peat, organic silts)

- Use of locally available materials (e.g., sand) for structural infill

- A reduction in pavement thickness by 50% with equivalent performance

- Excellent drainage for all weather-construction and all-weather access

These benefits translate into a lower environmental footprint: less aggregate and hauling, decreased in-situ earthworks and faster construction. Fuel use, vehicular pollution and the carbon footprint are reduced as well as construction time and costs.

Neoloy Geocell soil confinement locks aggregate in place and binds the soil particles. Enhanced surface adhesion prevents the generation of fines and dust, reducing the need for watering and chemical surface treatments. Neoloy Geocell reinforced road surfaces have very low degradation. They require less maintenance and positively affect rolling resistance factors – a key productivity indicator. For example, Neoloy Geocell stabilized roads improve traction and fuel economy, while lowering wear and tear on tires significantly. Smoother road surfaces also reduce downtime for vehicle maintenance, while improved operator safety increases truck speeds and hauling efficiencies.

In addition, Neoloy Geocells are self-draining systems that improve road drainage of the pavement and roadside drainage ditches (with concrete infill). These factors convert unpaved haul roads built with Neoloy Geocells into reliable all-weather roads.

The end result of using Neoloy Geocells is more efficient, safe and profitable hauling operations.

CASE STUDY: Neoloy Geocells enabled Suncor to create durable haul roads for heavy equipment on soft soil using reclaimed oil sands.

Challenge

Mining the Athabasca oil sands, in Alberta, Canada involves removing the overburden by shovel-and-truck operations. The overburden is comprised of water-laden muskeg (peat bog) on top of clay and barren sand with a CBR of <1% (California Bearing Ratio). The oil sands are typically 40-60 meters deep on top of limestone rock, which are excavated and hauled to a central processing facility.

Suncor, the world’s largest producer of bitumen, needed to strengthen the haul roads and loading areas of the processing facility for the huge haul trucks (650+ ton GMW – Gross Machine Operating Weight). The challenge was to provide durable pavement surfaces for extreme loading in the softest subgrade – in addition to -40°C temperatures. Freeze-thaw cycles cause heaving and distorts road surfaces.

Conventional Approach

Construction in muskeg-laden areas typically requires the complete removal of the soil and replacement with gravel – a complicated, costly and time-consuming solution. Chemical stabilization methods are expensive, hard to apply, detrimental to the environment and have unreliable durability. Temporary wood or steel ground can be used to bridge soft terrain; however, these are expensive, complicated to install and unsuitable for sustained use. Geogrids require specific aggregate types.

Neoloy Geocell Solution

Suncor chose the Neoloy Geocell soil stabilization as the only suitable solution. Neoloy Geocells improved the subgrade bearing capacity, while optimizing haul road performance using local resources. Neoloy Geocells (15 cm height) were installed in the base layer in single or dual layers as required; reclaimed sand from the bitumen processing was used as infill (15 cm + 3 cm overfill), and a 15 cm crushed stone was laid for the wearing course. The Neoloy Geocell forms a flexible mattress – or slab effect – that effectively ‘bridges’ over soft soil and attenuates ground movement from seasonal freeze-thaw cycles.

The high dynamic stiffness and tensile strength of the unique Neoloy Geocell technology enable the use of locally reclaimed sand of reclaimed sand – under the dynamic loading of mining and off-road construction equipment. In addition, the very high creep resistance of the Neoloy Geocell guarantees a durable road surface –maintaining compaction and performance under sustained heavy loading. In addition, Neoloy Geocell performs well even in fully saturated conditions and in a temperature range from -60° to +60°C.

Benefits

- Cost-effective solution for heavy-duty use in extremely weak soils

- Sustainable solution minimizes environmental impact

- Long-term durability minimizes downtime and optimizes profitability

2. Earth Stabilization for Site Rehabilitation and Waste Management

In addition to providing a firm base for haul roads, PRS Neoloy Geocells provides sustainable solutions that enable mining companies to better manage mine wastes and effectively rehabilitate the landscape at the mine end of life.

Sustainable Waste Management

The mission critical objective in mine waste management is to provide 100% protection of containment geomembranes while creating stable soil, berms and slopes. Neoloy Geocells integrated with geomembranes create impermeable, non-slip and durable impoundment for solid waste, leachate and liquids. The durable Neoloy novel polymeric alloy (NPA) is highly resistant to salinity, corrosion, acidity, chemicals and extreme temperatures for reliable long-term impoundment.

Neoloy Geocells hold slope infill material in place and prevent mass movement by providing high tensile reinforcement. Geo-liners are mechanically shielded by Neoloy Geocells from natural, accidental or intentional damage. Infill can be of concrete, gravel or topsoil for vegetation. Neoloy Geocells are also used for ground stabilization of containment pond beds to limit differential settlements that can stretch and damage the liners. Mining and energy concerns around the world have used Neoloy Geocells for safe and reliable environmental protection and waste management.

CASE STUDY: Neoloy Reinforcement to Expand Waste Containment Pond, India

Neoloy® Geocells were chosen to strengthen the foundation of unconsolidated mud embankment for waste containment pond.

Challenge

The Vedanta alumina refinery in Odisha India needed to strengthen the foundation of the 15,000 sq m embankment to support a 3m high addition to the earthen dyke to increase the storage capacity.

Neoloy Geocell Solution

Neoloy® Geocells were chosen to strengthen the foundation of unconsolidated mud embankment for mine waste management – due to their high stiffness, strength and resistance to creep.

Neoloy reinforcement contains and confines the shearing soil mass just below the foundation of the proposed dyke (footing). This transmits the footing pressure laterally and gives rise to higher load carrying capacity – by a factor of 4-6x. Slope stability was confirmed by analysis. The proven durability of the Neoloy polymeric alloy used in the geocells to withstand large stresses in a harsh chemical environment overtime gave a high degree of confidence to the solution.

Benefits

- Fast installation –completed in 15 days using locally available labor in a very remote area.

- Performance – embankment withstood monsoon rains with no deterioration.

- Cost-effective –much lower cost than engineered alternatives.

- Sustainable –locally available murrum soil was used for infill instead of importing high-quality granular materials.

Sustainable Site Rehabilitation

Extensive mining operations require mitigation to stabilize earth, protect slopes and prevent soil erosion. Neoloy Geocell 3D mechanical earth stabilization solutions are a best management practice to stabilize.

Neoloy Geocells confine, reinforce and restrain soil and rock infill. This prevents downslope movement from hydrodynamic and gravitational forces. High lateral confinement with soil-wall friction maximizes soil confinement. Long-term durability is provided by strong tensile strength, low creep and high UV protection.

Neoloy Geocell is an excellent solution for revegetation. Perforations in the cell walls enable soil-root interlock that stabilizes the soil mass, while the cells provide a mechanically protected growth stratum. Neoloy Geocells are an ideal method for restoring natural land cover and landscape aesthetics.

Neoloy Geocells provide sustainably engineered landscapes and cost-effective solutions for waste stack mitigation, as well as channel diversion, retention walls, embankments and containment ponds.

CASE STUDY: Mine Site Rehabilitation and Slope Reinforcement, Poland

Neoloy Geocells are the base of this sustainable solution that transformed a huge mountain of waste into a multi-use regional recreational site, forest and tourist attraction.

Challenge

After 30 years of brown coal production in the Bełchatów lignite mine, Poland (200 billion-ton total reserves), a 200m high x 4 km wide hill / dry stack was created from 1.350 billion m3 of overburden. The local town council together with mine owner, the PGE Group, decided to rehabilitate the Kamieńsk Mountain of solid waste and turn it into a multi-use recreational site.

Neoloy Geocell Solution

To resolve the daunting geotechnical and environmental challenges of the project, the PGE Group selected the Neoloy Geocell 3D mechanical stabilization solution. Neoloy Geocells – made of novel polymeric alloy – is the strongest, most effective and most durable method to protect the slopes, prevent soil erosion and enable revegetation of what became the highest hill in central Poland.

Neoloy Geocells were installed and anchored on the slopes, ranging from 20-80-degree inclines. The cells were filled with poor grade waste material and covered with local topsoil. The Neoloy Geocells increased the frictional interaction, improved drainage and prevented runoff to stabilize the slope soils. The perforated cells also allow root-soil interlock and a growth stratum for replanting – that included reforestation of over 25 natural species of trees.

Neoloy Geocells were the ‘foundation’ of this project that transformed a large environmental nuisance into Mt. Kamieńsk, an attractive multiple-use recreational site, boasting a sports center, rides, skiing facilities and tens of kilometers of bike trails, along with a 30 MW wind turbine farm at the top of the mountain.

This hugely successful project is an example of sustainable mining that encompasses the environmental, social and economic aspects of mining activities.

Client Benefits

- Effective and durable soil and slope protection for restore natural landscape

- Transform waste into recreation site with social, economic and environmental value

- Outstanding example of sustainable mining rehabilitation